Description

Description

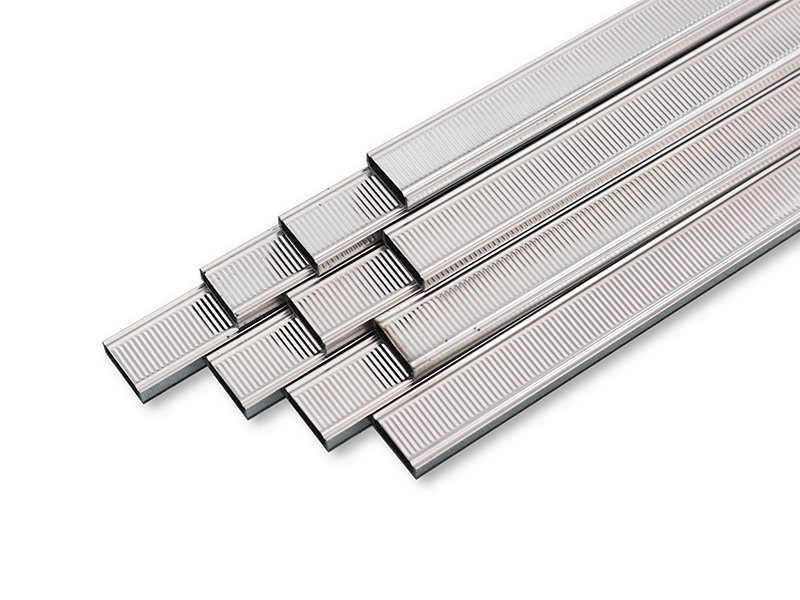

The roller coating process for aluminum spacers mainly solves the problem of side spray bending without white leakage, which is our company's focus on the surface of aluminum coils Color roller coating treatment is applied on top, and then processed into aluminum partition strips, which have a higher level of decorative effect.The paint film thickness is not less than 12 microns,and there are 1-2mm layers on the side, which is more beautiful and tidy.

Processing technology

Hollow aluminum partition strip (hollow aluminum partition frame) is an aluminum product made of 3003 alloy aluminum as raw material, using internationally advanced compression molding technology Technology and high-frequency welding process, without damaging the molecular structure of raw materials, ensuring molecular activity, without distinction during bending and filling Crack phenomenon.

Technical requirement

Wall thickness: The unilateral wall thickness is guaranteed to be between 0.3-0.35mm, and the maximum deviation of the peripheral wall thicknessis ± 0.025mm;Bending degree: The product is not allowed to have hard bend or side bends (excluding free sag bending curvature);Appearance: The surface is flat and smooth, without bumps, and the pores are uniform and neat.

Introduce

Hebei Xinjian Metal Products Co., Ltd. covers an area of 50,000 square meters. It is a modern high-tech enterprise and a large-scale enterprise specializing in the research and development, manufacturing, sales and technical services of high-performance insulating glass accessories.

Customized Process

Products can be developed and manufactured according to drawings or samples provided by customers.We have an experienced R&D team focused on technological innovation and product upgrades to ensure that product performance is always at the industry-leading level.

Online communication

Provide custom drawings

Merchant quotation

Sign a contract

Processing and production

Packaging and distribution

Confirm receipt of goods

Successful transaction

FAQ

Can you accept small quantities?

Yes, accept small quantity, fast delivery

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

What is the minimum order quantity?

It depends on the product.

Previous

Roller coated aluminum spacer strip

You still doubt it? First get samples contact us!

subcategory

Immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!